Automotive Vision System

KbPort™ was presented with a unique opportunity to use our cutting-edge artificial intelligence (“AI”) technologies to solve a difficult problem for one of the “Big Three” American automotive manufacturers.

The Challenge

There is a common problem within the engine manufacturing process. A critical component, called a cam follower, which is currently placed by hand, can potentially be installed backwards and can also fall out of position. Exacerbating the problem, these parts are nearly symmetrical, making it easier to confuse the correct position for the incorrect position. Starting an engine with the cam followers backwards or out of position will destroy the engine entirely. Clearly, this is a major problem.

Our Solution

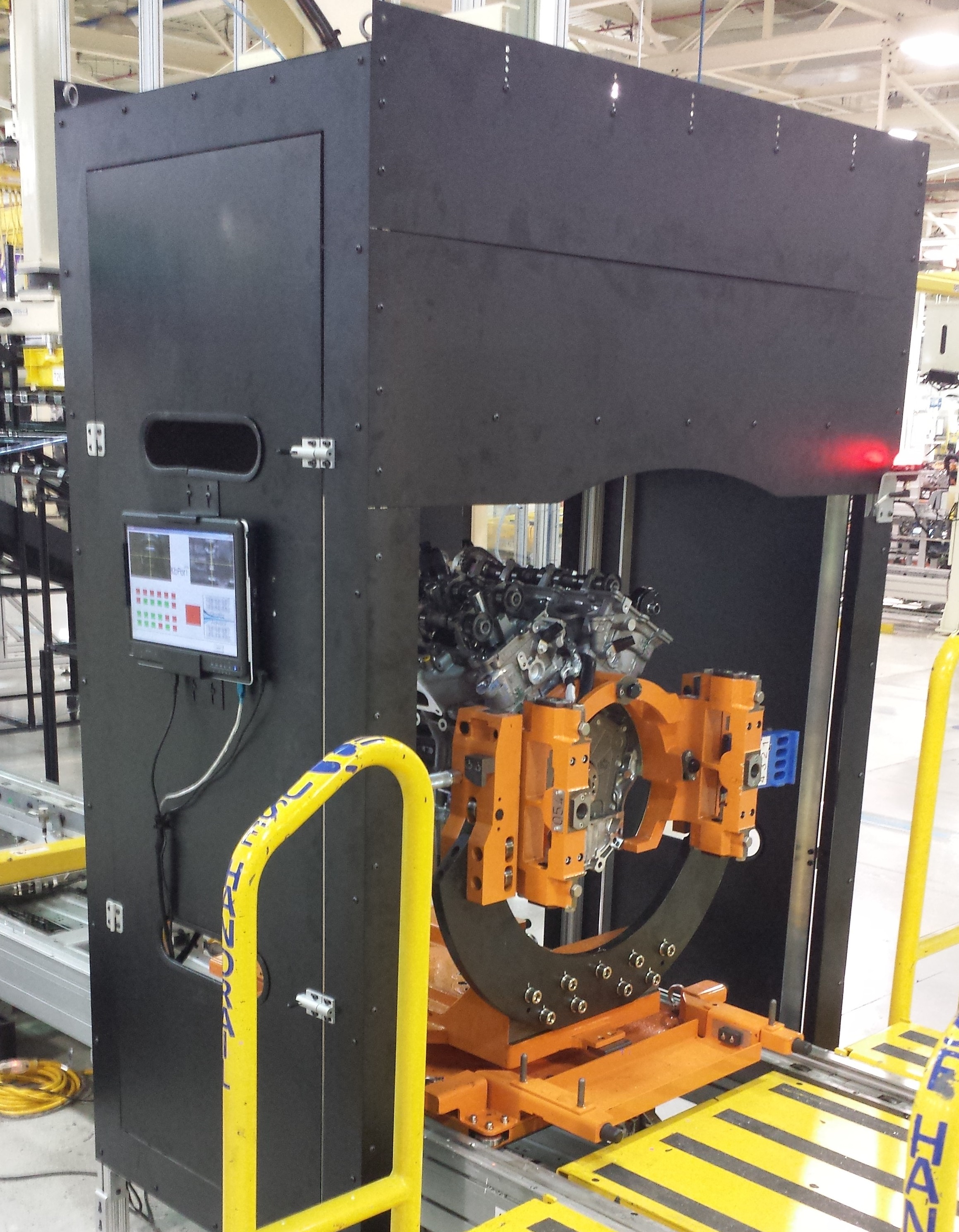

Using our existing technology as a foundation, KbPort™ created an innovative AI system built upon neural networks to analyze engines on the assembly line. This camera system captures images of the engines an is able to programmatically determine whether or not all of the cam followers are in the proper position. The system functions quickly enough not to induce delays in the production line. Once the engine has been analyzed, and any misaligned cam followers identified, workers have an opportunity to correct the cam followers before damage to the engine can occur.

Gallery

Assembly Line: Inspection Station